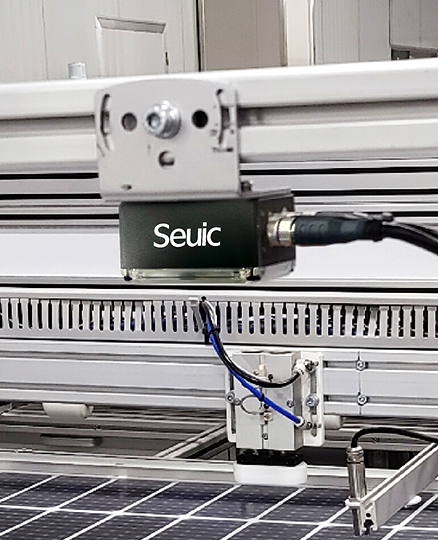

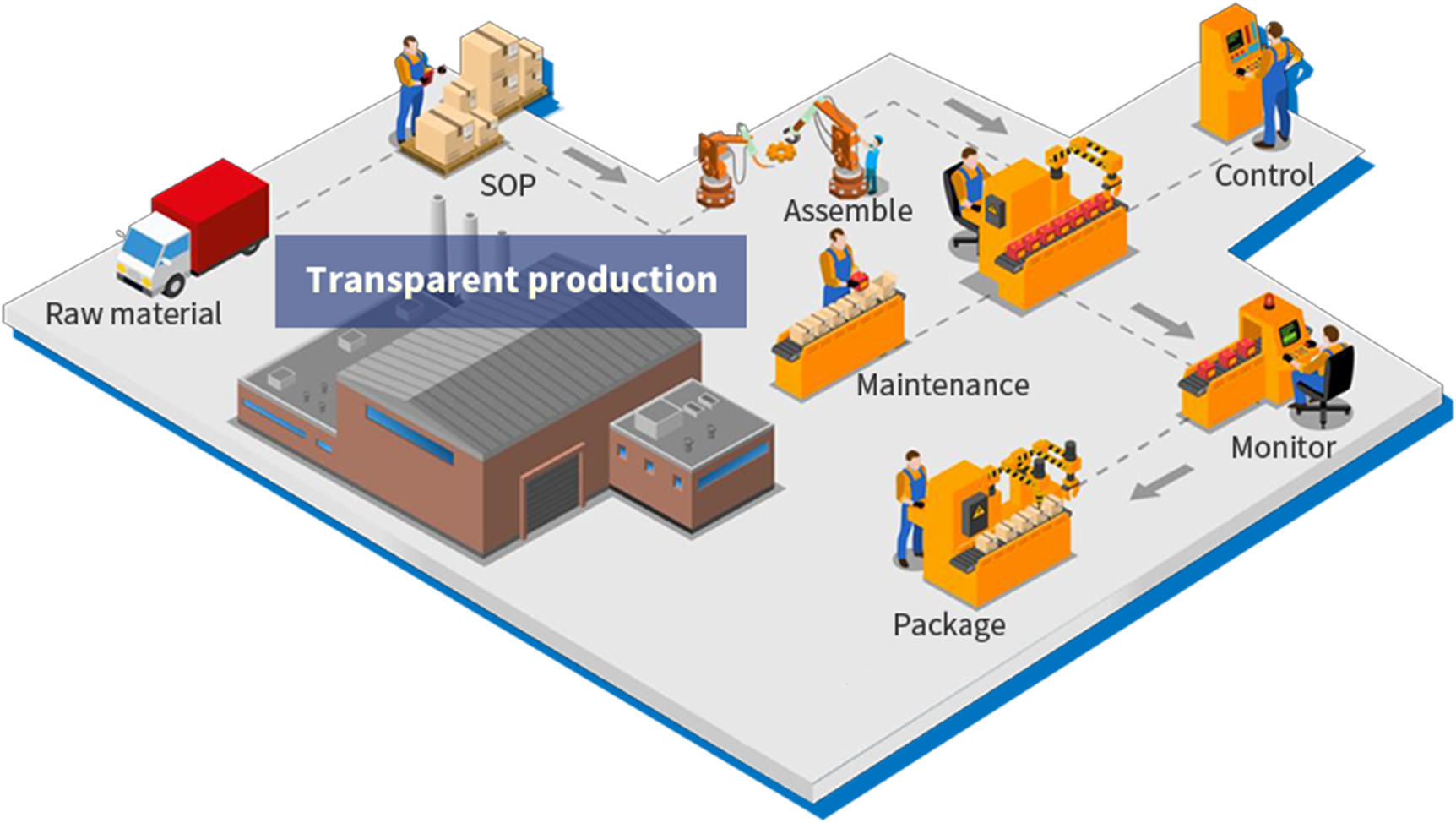

Whether the data is real-time, accurate and detailed has become one of the important indicators of successful smart manufacturing. Through the application of RFID products, Seuic help to make an informatization plan in the links of production line information collection/traceability, in/out stock, technical guidance, process reporting and defect check, etc. Meanwhile, Seuic is dedicated to increasing the 3 main key indicators of production efficiency, order delivery ability and inventory turnover level to speed up digitalization.