Brief Introduction

Brief introduction of Fuhua Weaving

Founded in the 1980s, Wujiang Fuhua Weaving Co., Ltd. is now recognized as a large-scale textile enterprise that integrates fabric research and development, weaving, and finishing. The entire industrial park spans an area of nearly 300,000㎡ and is equipped with over 3,000 sets of internationally advanced water jet looms, 17 sets of preparation and supporting equipment, and more than 20 sets of finishing machines. With an annual production capacity exceeding 300 million meters of greige fabric and over 100 million meters of dyed fabric, its business reaches global markets, including Southeast Asia, Europe, North America, and others.

However, like many traditional industries, Fuhua Weaving faced several challenges in their production management systems.

Business Pain Points

The textile industry is intricate, and traditional management systems like ERP (Enterprise Resource Planning) and MES (Manufacturing Execution Systems) often rely on tranditional methods such as barcode labels or manual documentation. These methods, while functional, come with significant limitations:

1. Paper barcodes are not resistant to dirt, moisture, and easily damage, making them unsuitable for long-term use: Traditional paper barcodes degrade quickly in challenging environments, becoming unreadable when exposed to dirt, moisture, or wear. This makes them unreliable for long-term or industrial applications.

2. Manual scanning is cumbersome and requires too much human involvement, reducing accuracy and real-time efficiency: Manual barcode scanning is labor-intensive and prone to errors, leading to inefficiencies in speed and accuracy, especially in high-volume operations.These challenges created gaps in Fuhua Weaving's ability to manage raw material flows, track production processes, and ensure data accuracy across the board.

The RFID Solution with Seuic AUTOID UF2-C RFID Reader

To address these issues, Fuhua Weaving turned to RFID technology with Seuic fixed RFID reader, AUTOID UF2-C, enabling a more automated and accurate management system. Here's how RFID transformed their operations:

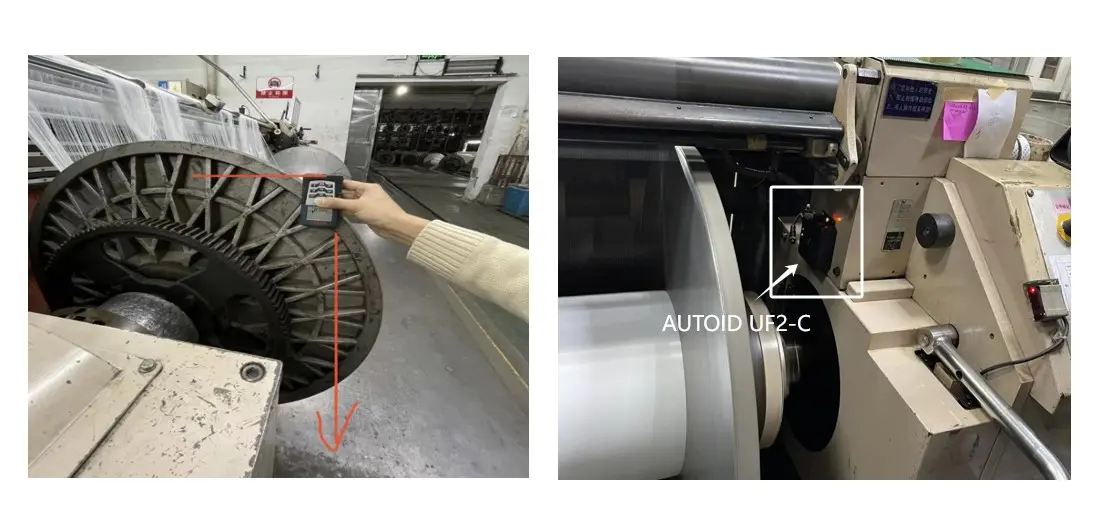

Durable RFID Tag Installation: ABS anti-metal RFID tags are installed on the warp beams to enable long-term use. These tags are resistant to the metal surface of the beam, ensuring reliable performance over time.

Automated Reading with UF2: The Seuic UF2 device is used to automatically read the RFID tags on the warp beams. In addition to reading, the UF2 records the triggering of the photoelectric switch, marking the start and end of the process.

Seamless Integration with ERP/MES Systems: By transmitting data from the UF2 to the central control system, the entire process of loading and unloading the warp beam is monitored automatically. This ensures accurate, real-time data updates for ERP/MES systems, enhancing operational efficiency and data integrity.

The Benefits of RFID Reader Integration

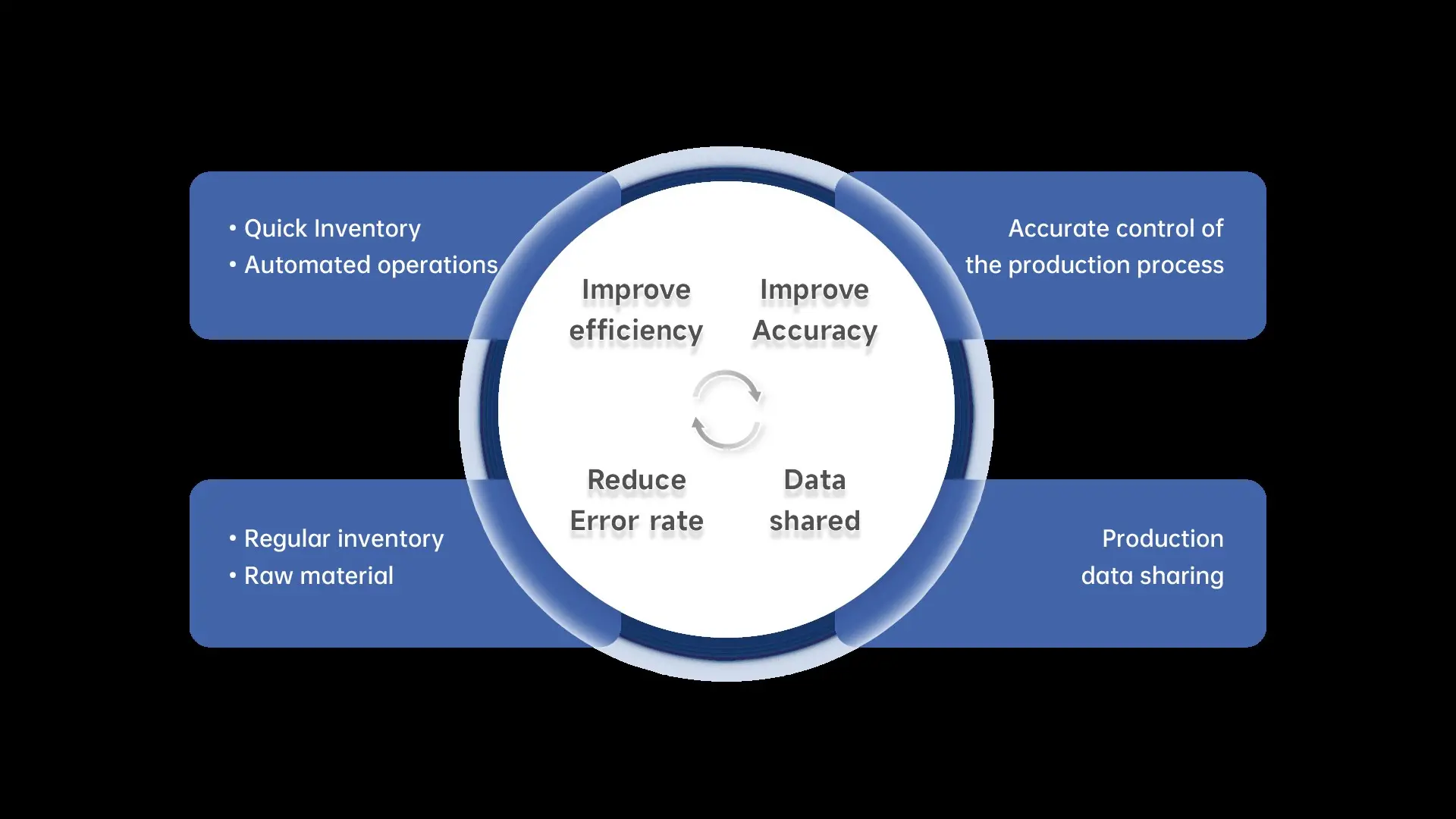

Fuhua Weaving's adoption of RFID has yielded significant improvements in their operations. Key benefits include:

Fully Automated Data Collection: The integration of Seuic RFID products triggers automatic data reading during the production process, significantly reducing human intervention. This advancement has led to a data collection efficiency improvement of over 100%.

Enhanced Timeliness and Accuracy of ERP/MES Data: RFID technology enables automatic and efficient data collection, along with real-time monitoring of the production process. This capability not only improves the accuracy of the data but also reduces operational costs, ensuring that ERP/MES systems receive timely and precise information.

- Hotel Operations Go Smart: RFID at Fairfield by Marriott2025-10-29

- Smart Tech Behind the Counter: Driving Digital Transformation in Food Retail2025-06-13

- How a Leading Coffee Chain Digitized Store Operations with RFID2025-05-14

- Unlocking Efficiency at China Eastern Airlines with RFID Technology2024-10-25

- How RFID Technology Boosts Textile Manufacturing Efficiency2024-10-24